Day 7: Fabric Manufacture for over 20 years Reacts to "Fabric Tok"

- Ira Bashist

- Dec 22, 2025

- 3 min read

Welcome to Day 7—of My Dad vs. The Algorithm.

We are ending the week by exposing the biggest secret in the fashion district: Where that "exclusive" ready-to-ship fabric actually comes from.

I showed my dad, Ira, a popular TikTok where a seller claims: "Don't let manufacturers gatekeep! We have NO minimums! We ship in 24 hours! Start your brand today!"

Ira’s Reaction:

"They aren't telling you the full story. You aren't 'starting a brand.' You are stepping into the end of a long supply chain story. And if you build your business on that video, you're going to hit a wall."

Here is the reality of the supply chain that TikTok doesn't show you.

1. The "Secret Life" of that Fabric Roll

Let's look at that specific scenario. You find a TikTok shop selling 100 yards of "Vintage Wash French Terry" for a higher price with no wait time. You buy it. You sell out. You come to Greene Textile asking if we stock something similar ,what’s the minimum and how long to make something similar for more.

Here is why that fabric existed in the first place:

The Origin: That 100 yards didn't just appear. It is leftovers from a brands that did the work. Most dead stock doesn’t come from Manufactures standard stock styles, they come from their custom style line.

The Real Order: Weeks ago, a serious brand ordered 1,000 yards from a manufacturer. They waited the 2-4 weeks for production.

The Overflow: The factory produced and there were potential damages, or the brand ordered too much and dumped the rest.

The Trap: That TikTok seller bought the scraps. When you buy from them, you are buying the tail end of someone else's production run.

The Reality Check: The manufacturer didn't change their minimums or the styles they stock. The lead time didn't change. The TikTok video just sold you the promise of quick delivery without telling you that once they are gone, they are gone forever.

2. The "Amazon Prime" Delusion

This creates a dangerous expectation: "Why can't the factory ship colors in one week like the TikTok account?"

Ira’s Take:

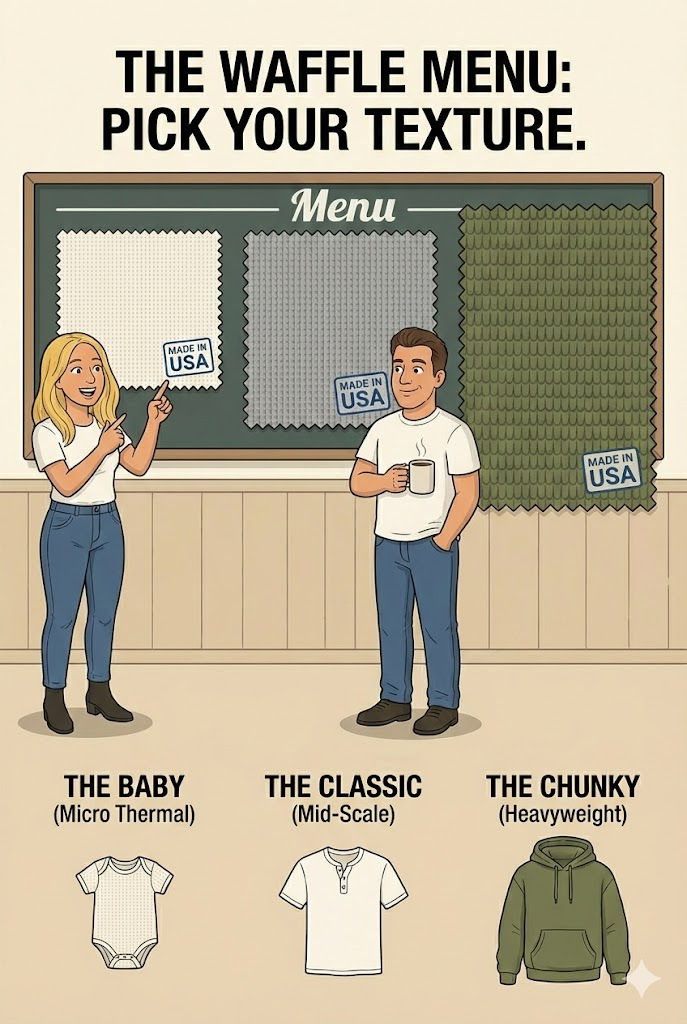

People expect quick delivery, similar to Amazon Prime. At Greene Textile, we stock raw, un-dyed knit fabric called "Greige Goods" for popular styles. We can't read minds. Once you send the order, we dye, wash, dry, and inspect the fabric, rather than simply pulling a finished roll from a shelf. This process takes time; dyeing alone can take up to 5 days. We also inspect the fabric to ensure quality, which takes additional time. If the customer accepts uninspected fabric and we have the Greige Goods, we can ship in about a week. Custom colors require lab dips, customer approval, dyeing, and inspection, which takes longer, especially for orders with multiple colors or large quantities. Planning at least 14 days ahead is crucial for quality. For in-house finished PFD fabric, we can ship within 24-48 hours if pre-planned. Like Amazon, we sometimes run out of stock and need to restock.

3. Feeding the "Deadstock Monster"

There is a massive push on social media that buying "Deadstock" is sustainable. In reality, relying on jobbers feeds the cycle of waste.

No Continuity: You buy a roll today. You love it. You go back next month... and it's gone. Jobbers sell leftovers. You cannot build a consistent brand on disappearing ingredients.

The Cycle of Waste: Buying "what's available" encourages big mills to over-produce because they know jobbers will buy the excess. It also encourages brands to be irresponsible—ordering fabric then deciding they aren’t going to make as much as they planned to because they know they can dump the "deadstock" on the market later.

True Sustainability: When you order from us, you get exactly what you need.

Custom: You order the minimum, we make exactly that amount.

Stock: You buy from our in-house stock (min 1 roll). This isn't random scrap; it's first-quality fabric we produced intentionally.

The Bottom Line

There is a difference between a Shopper and a Sourcing.

Shoppers buy what is available right now (Jobbers/TikTok). They get instant gratification but zero future.

Sourcing plan ahead and partner with a factory (Manufacturers). They get consistency, quality, and a partner who can scale with them.

Hey guys, welcome back to the factory!" 🤳✨ Ira and Alex take over the feed to show you what real sourcing looks like (no gatekeeping, just facts)

Ira’s Final Advice:

"Don't let TikTok run your supply chain. If you want quality, you need patience. If you want a future, stop buying fast food and start making your own meal."

Ready to stop limiting you brand with using fabric you can get right now? Check our In-House Stock for high-quality basics (minimum 1 roll) or start your Custom Production.

Comments