Day 21: "Made in USA" vs. "Sewn in USA" (The Kitchen Rule)

- Ira Bashist

- 7 days ago

- 3 min read

Welcome to Week 3, Day 21 of My Dad vs. The Algorithm.

Today we are talking about The Recipe.

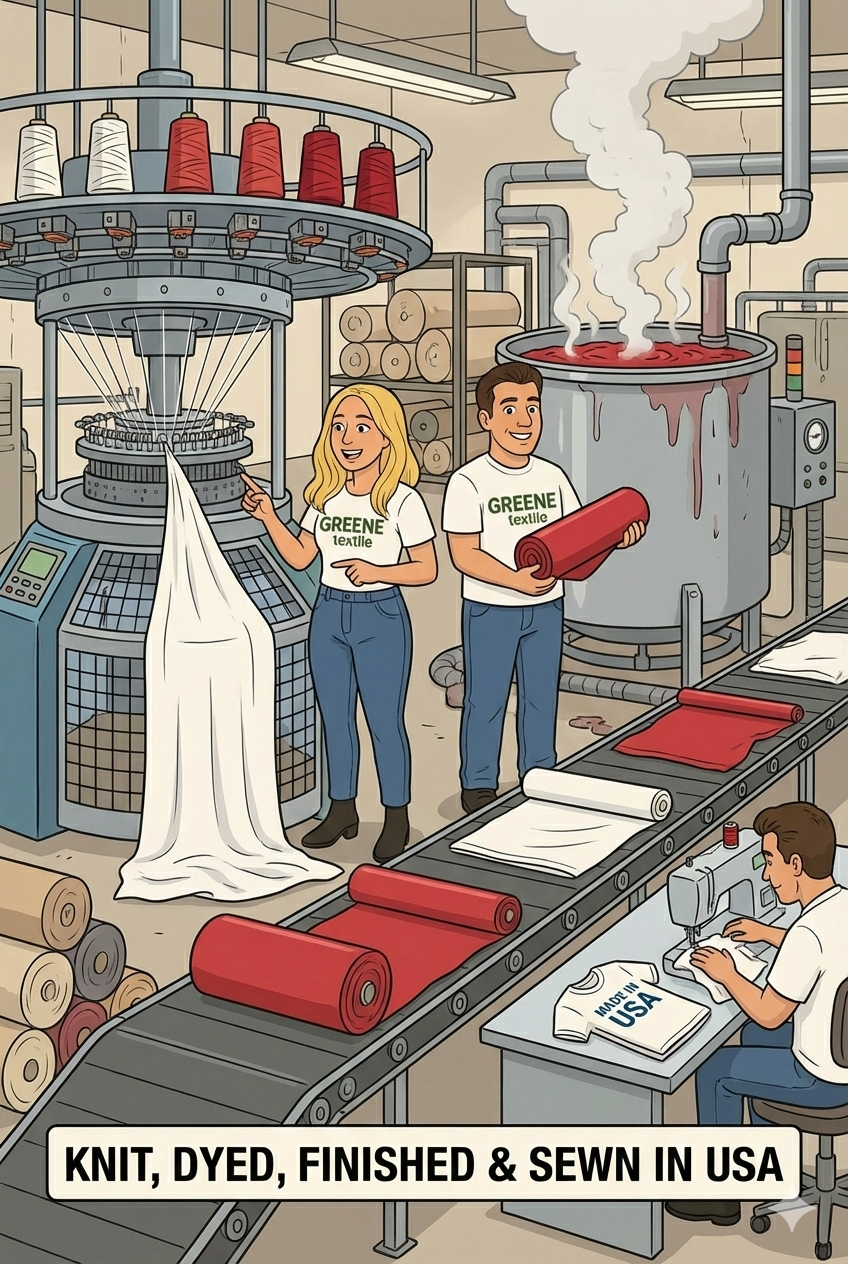

We see a lot of brands claiming "Made in USA" because they have a sewing room in downtown Los Angeles. But when you look at their fabric, it was knit, dyed, and finished overseas, then shipped here on a boat to be stitched together.

My dad, Ira, calls this "The Frozen Pizza Method."

Ira’s Take:

"If you buy a frozen pizza from Italy and just heat it up in a New York oven, did you 'make' that pizza in New York? No. You just warmed it up.To really claim American manufacturing, you can't just do the last step. You have to cook the meal here. That means Knitting, Dyeing, and Finishing."

The "Sewing" Misconception

There is a massive difference between Manufacturing a garment and Assembling a garment.

The FTC has strict rules about this. If a brand buys finished fabric from China and only sews it in Los Angeles, they usually have to label it "Made in USA of Imported Fabric." They cannot simply say "Made in USA" because the "main ingredient"—the fabric itself—wasn't created here.

To us, "Made in USA" means the fabric was actually born here.

The Real Work Happens Before the Sewing

When we say our fabric is Made in USA, we aren't talking about a sewing machine. We are talking about the heavy industrial work that determines the quality of the product:

1. Knitting (The Structure) 🇺🇸 This is where the magic happens. We run the machines here in Los Angeles to create the physical structure of the fabric. We control the tension, the weight, and the feel on American soil.

2. Dyeing & Finishing (The Chemistry) 🇺🇸 This is the most critical step for quality control. We dye, wash, and shrink-test the fabric in local dye houses. By doing this domestically, we ensure the color is consistent and the fabric is stable before it ever gets cut.

3. Cut & Sew (The Assembly) 🇺🇸 Finally, the fabric is cut and sewn into a finished shirt.

Why It Matters

If you skip steps 1 and 2, you are just an assembler. You are importing someone else's engineering and just adding a stitch.

Ira’s Lesson:

"The sewing machine is just the stapler. The real quality comes from the Knitting and the Dyeing.If you import the fabric, you're importing someone else's standards. When we Knit, Dye, and Finish here, we control the recipe. We know exactly what's in the sauce because we made it from scratch."

The Bottom Line

Labels are promises of quality.

Authentic American manufacturing isn't just about where the needle touches the cloth. It's about where the fabric was created.

Ira’s Final Advice:

"Don't let them fool you with a flag on the tag. Ask them: 'Where was this knit? Where was this dyed?' If they can't tell you, they didn't make it. They just assembled it."

Tune in tomorrow for Day 22!

(Missed yesterday's post about Pique vs. Jersey? Read Day 20: The Limp Noodle Collar here.)

Support authentic American manufacturing. Shop our Made in USA Fabric Collection.

Comments