Guide to Measuring Fabric Weight

- Ira Bashist

- Jan 22

- 4 min read

When it comes to choosing the right fabric for your clothing line or design project, understanding fabric weight is like having a secret weapon. It tells you how heavy or light a fabric feels, which affects everything from comfort to durability. But how do you measure fabric weight accurately? And what does it really mean when someone says a fabric is "12 oz"? Let’s dive into the world of fabric weight and unravel these questions together.

Understanding Fabric Weight Guide: Why It Matters

Fabric weight is more than just a number. It’s a key factor that influences the look, feel, and function of your garments. Whether you’re designing cozy hoodies or breezy summer dresses, knowing the weight of your fabric helps you make smarter choices.

Fabric weight is usually measured in ounces per linear yard (oz/lnyd) or grams per square meter (gsm). The higher the number, the heavier and thicker the fabric. For example, a 7 oz fabric is lightweight and perfect for shirts, while a 12 oz fabric is much heavier.

Why should you care? Because fabric weight affects:

Durability: Heavier fabrics tend to last longer.

Comfort: Lightweight fabrics breathe better.

Drape: How the fabric falls on the body.

Seasonality: Heavier fabrics are great for cold weather; lighter ones for warm.

If you want to get into the nitty-gritty of fabric weight measurement, check out this fabric weight measurement resource for detailed insights.

How to Measure Fabric Weight: A Step-by-Step Fabric Weight Guide

Measuring fabric weight might sound technical, but it’s actually pretty straightforward. Here’s a simple fabric weight guide you can follow at home or in your studio:

Cut a Sample: Take a piece of fabric, usually 1 yard

Weigh the Sample: Use a precise scale that measures in grams or ounces, then multiple by the width. Or use a website that allows you to enter your measurements.

Calculate the Weight: If you used a 1 yard weigh linear what you get in the yard no matter what the width is stays the same, 1-yard square , the weight you get is the fabric weight in oz/yd². For metric, it’s grams per square meter (gsm).

F

Pro tip: Always use a digital scale for accuracy. Even a small difference can change your fabric’s classification.

This method is especially useful if you’re sourcing fabric from a manufacturer and want to verify the weight before placing an order. At Greene Textile Inc., our low minimums come from our house made stock in PFD (Prepared For Dyeing), so you can test and feel the fabric before committing.

What Does 12 oz Fabric Mean?

You might have heard the term "12 oz fabric" tossed around, especially when talking about denim or heavy cotton. But what does it really mean?

A 12 oz fabric means that one square yard of this fabric weighs 12 ounces. This weight is considered medium to heavy and is often used for durable clothing like jeans, jackets, and sweatshirts. It strikes a balance between sturdiness and comfort.

Here’s why 12 oz fabric is popular:

Durability: It can withstand wear and tear.

Structure: Holds shape well without being too stiff.

Versatility: Suitable for both casual and workwear.

If you’re designing a clothing line that needs to feel substantial but not bulky, 12 oz fabric might be your sweet spot. It’s also a favorite among brands looking for quality and longevity.

Choosing the Right Fabric Weight for Your Project

Picking the right fabric weight can feel like navigating a maze. But here’s a simple way to think about it:

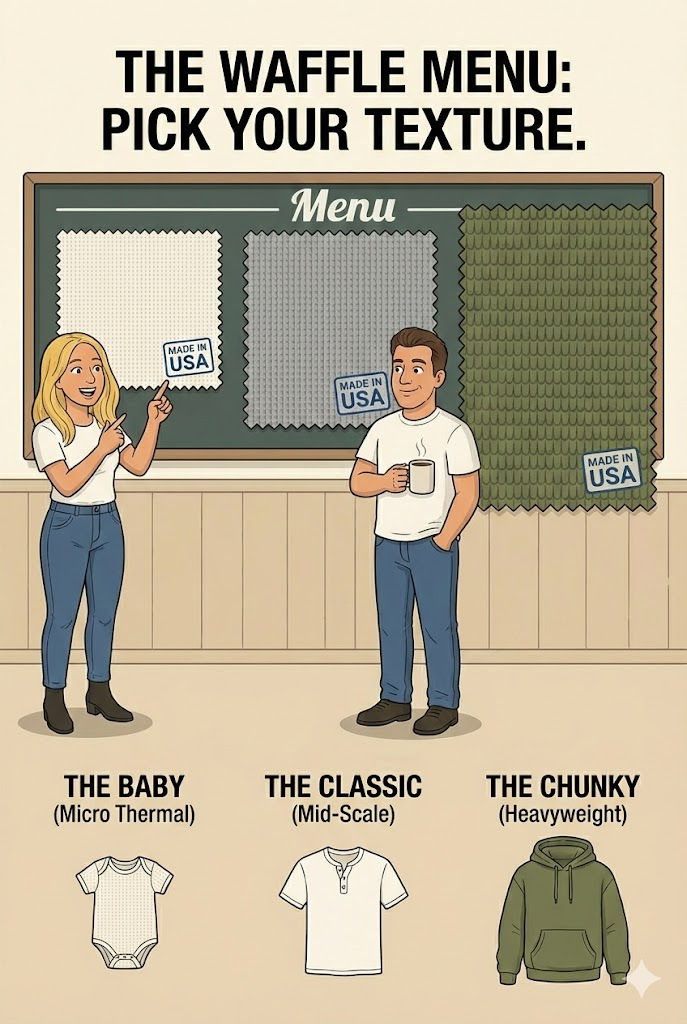

Lightweight (under 4 oz): Great for blouses, linings, and summer wear.

Medium weight (4-8 oz): Perfect for shirts, dresses, and light jackets.

Heavyweight (8-12 oz and above): Ideal for denim, sweatshirts, and outerwear.

Ask yourself:

What season will the garment be worn in?

How much structure do you want?

Will the fabric need to hold up to frequent washing?

For example, if you’re making organic cotton tees, a medium weight fabric around 5-6 oz is comfortable and breathable. For custom knits or heavier outerwear, you might want to explore 10-12 oz options.

Remember, at Greene Textile Inc., we specialize in quick, high-quality, and locally-made fabrics right from Los Angeles. Our house made stock in PFD means you can get exactly what you need without waiting weeks.

Tips for Working with Fabric Weight in Production

Once you’ve chosen your fabric weight, here are some tips to keep your production smooth:

Test before bulk ordering: Request samples to feel the weight and drape.

Communicate with your manufacturer: Make sure they understand your fabric weight needs.

Consider shrinkage: Heavier fabrics may shrink differently.

Adjust sewing techniques: Heavier fabrics might need stronger needles and different stitch lengths.

By paying attention to these details, you’ll avoid surprises and create garments that meet your quality standards.

Final Thoughts on Fabric Weight and Your Brand’s Success

Understanding fabric weight is like having a compass in the vast sea of textile options. It guides you to fabrics that fit your vision and your customers’ needs. Whether you’re designing organic knits or durable denim, knowing how to measure and interpret fabric weight helps you make confident decisions.

If you want to explore more about fabric weight and how it impacts your designs, don’t hesitate to reach out to manufacturers who offer low minimums and house made stock in PFD. This way, you get the best of both worlds - quality and flexibility.

Remember, every great garment starts with the right fabric. So take your time, measure carefully, and watch your creations come to life with the perfect weight behind them. Happy designing!

Comments