Day 8: The "20s Yarn" Myth & The Custom Trap

- Ira Bashist

- Dec 23, 2025

- 4 min read

Updated: Jan 6

Welcome to Week 2, Day 8 of My Dad vs. The Algorithm.

We are kicking off the second week by diving deep into the technical weeds. Today’s topic covers two of the most expensive mistakes new brands make: obsessing over a specific Yarn Count and demanding Custom Yarns.

I showed my dad, Ira, a viral video from a "streetwear brand guru" who declared: "If you want a true luxury heavyweight tee, you MUST tell your manufacturer to use 20s single cotton yarn."

Ira’s Reaction:

"Who is teaching these kids? That’s like walking into a bakery and telling the baker precisely which brand of flour to use, but not telling him if you want a light sponge cake or a dense brownie. Stop ordering ingredients. Start ordering the meal."

Here is why obsessing over a specific yarn count—like 20s—is a rookie mistake, and why flexibility is your best friend.

The Misconception: "Yarn Count = Fabric Weight"

New designers often think yarn count is a cheat code for fabric weight. They read somewhere that "20s singles" is good for streetwear, so they insist on it.

The Reality: Yarn count only tells you how thick the individual thread is. It tells you almost nothing about how heavy the final fabric will be.

Ira’s Take:

"Yarn is just raw material. I’m the knitter; I control the density. You want a 20s yarn? Fine. I have pallets of it. I can take that 20s yarn and knit it loosely on the machine to make a breezy 8 -9oz/ly (ounces per linear yard) fabric like our style #4184. Or, I can take that exact same yarn, tighten the tension, squeeze more stitches per inch, and make a dense, structured 16 oz/ly fabric like our #4165. It’s the same yarn. The machine settings determine the final weight just as much as the ingredient does."

The "Custom Yarn" Trap

This obsession leads to another problem: designers demanding weird, non-standard yarn counts because they think it's the only way to get a unique feel.

The Reality: Manufacturing is a game of scale. We stock standard yarn counts that are popular and versatile. If you insist on an odd count that nobody else uses, it requires a special order from the yarn spinning mill.

Ira’s Take:

"If you demand a weird yarn count, you are signing up for high minimums, long lead times, and higher prices. You are making your own life harder. Instead, let me use a standard yarn that I have sitting on my floor right now. I know how to manipulate my machines to take that standard yarn and give you the unique weight and handfeel you're looking for. It’s the same result, but it’s faster and cheaper for you. Don't reinvent the wheel just to feel special; let me customize the ride."

The Fix: Stop Ordering Inputs, Start Ordering Outputs

When you email a manufacturer asking for "20s single jersey," you are trying to do our job for us. You are focusing on the input.

Instead, focus on the Output. Tell us what you want the final product to feel like and weigh. In the US, we typically measure fabric weight in Ounces Per Linear Yard (OZ/LY).

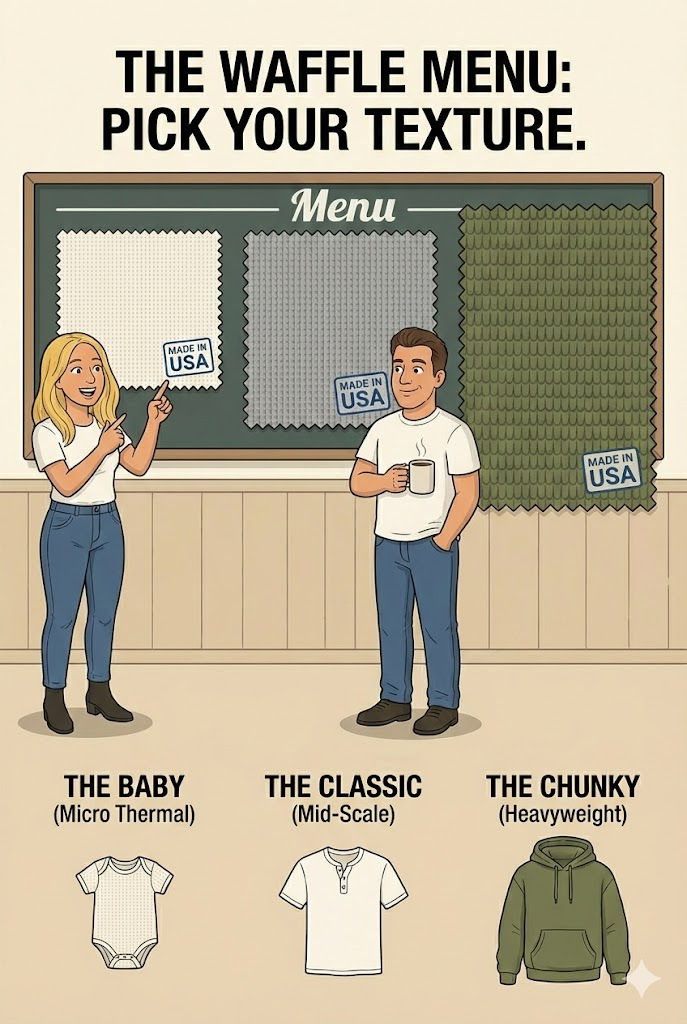

The Cheat Sheet to OZ/LY:

4 oz – 6 oz/ly: Lightweight. Drapey, sheer, vintage feel.

7 oz – 9 oz/ly: Midweight. Your standard, everyday t-shirt.

10 oz – 16+ oz/ly: Heavyweight. Structured, boxy, premium streetwear feel.

The Bottom Line

Don't come to us specifying ingredients and cooking times. Come to us and tell us what meal you want to serve your customers.

Don’t say: "I need a 20s single combed cotton knit at 28 gauge."

Do say: "I need a 12 oz/ly heavyweight jersey. Use whatever standard yarn gets me there best."

Ira has been knitting since 2001. Trust the chef to pick the right ingredients for the meal you want.

Why Flexibility Matters

Flexibility in your fabric choices can lead to better results. When you allow your manufacturer to guide you, you open the door to creativity. You might discover a fabric that exceeds your expectations.

Understanding Fabric Characteristics

Different fabrics have unique characteristics. Some may drape beautifully, while others may provide structure. Understanding these differences can help you make informed decisions.

The Importance of Samples

Before committing to a large order, always request samples. This allows you to feel the fabric and see how it behaves. It’s a crucial step in ensuring you get exactly what you want.

Building a Relationship with Your Manufacturer

Establishing a good relationship with your manufacturer can be invaluable. Open communication leads to better understanding and results. Share your vision and trust their expertise.

Conclusion

In the end, the goal is to create a product that resonates with your audience. By focusing on the final output rather than the inputs, you can streamline the process. Remember, it’s not just about the yarn count; it’s about the experience you want to deliver.

Tune in tomorrow for Day 9!

Not sure what 10 oz/ly feels like compared to 14 oz/ly? Order our **Essential Swatch Kit and feel the difference yourself.

Comments