Greenetextile Montebello: A Fabric Manufacturer Spotlight

- Ira Bashist

- Oct 1, 2025

- 5 min read

When it comes to sourcing quality fabric for your clothing line or design projects, finding a reliable manufacturer can feel like searching for a needle in a haystack. But what if I told you there’s a gem right in Los Angeles that offers not only high-quality fabrics but also the flexibility and speed that small businesses and designers crave? Let’s dive into the world of fabric manufacturing with a special focus on Greene Textile , a standout in the industry.

Understanding Greene Textile Fabric Production

Fabric production is more than just weaving threads together. It’s an art and science combined, where quality, sustainability, and innovation meet. Greene Textile fabric production is a perfect example of this blend. They specialize in creating custom orders and organic fabric options that cater to brands looking for something unique and eco-friendly.

What sets them apart? For starters, their low minimums policy means you don’t have to order a mountain of fabric to get started. This is a game-changer for small businesses and designers who want to test new ideas without a huge upfront investment. Their house-made stock in PFD (Prepared For Dyeing) gives you a head start on customization, allowing you to bring your vision to life faster.

Imagine having a fabric manufacturer that feels like an extension of your creative team. That’s what working with Greene Textile feels like. They understand the clothing is much more than something you wear, but a creative outlet that also creates an ecosystem that feels like family.

The Fabric Manufacturing Process at Greene Textile

Let’s break down the fabric manufacturing process to see why Greene Textile stands out. It all begins with sourcing the right fibers. They focus heavily on organic and sustainable materials, which means your fabric isn’t just beautiful but also environmentally responsible. We source all of our yarns from local LA yarn suppliers who have relationships with yarn factories all of the world.

Next comes the knitting or weaving stage. Greene Textile uses local knitting mills to produce custom knits that meet your exact specifications. Whether you need a soft jersey knit for t-shirts or a sturdy rib knit for sweaters, they’ve got you covered.

After the fabric is produced, it’s prepared for dyeing or printing. This is where their house-made stock in PFD shines. Having fabric ready for dyeing means you can skip some of the waiting time and get your colors just right. Plus, their local production in the greater Los Angeles area, means faster turnaround times compared to overseas manufacturers.

Finally, quality control ensures every yard of fabric meets strict standards. This attention to detail helps reduce waste and ensures your products look and feel premium.

However, for clothing brands and designers looking for custom, organic, and locally produced fabrics, these large suppliers might not always be the best fit. Their minimum order quantities can be huge, and their focus is often on mass production rather than customization.

This is where manufacturers like Greene Textile shine. They fill the gap between large-scale suppliers and small businesses by offering flexibility, quality, and sustainability all under one roof. Their commitment to local production in Los Angeles means you get faster service and a partner who understands your needs.

Why Choose Greene Textile Montebello for Your Fabric Needs?

You might be wondering, “Why should I consider Greene Textile in Montebello for my fabric production?” Here are some compelling reasons:

Local Production: Being based in Montebello, California, means shorter shipping times and easier communication. No more waiting weeks for overseas shipments.

Low Minimums: Their low minimum of mix fabrics in one order to meet the 800-1000 yard minimum quantities make it accessible for startups and brands to experiment and grow.

Sustainability Focus: They prioritize , helping you build a brand that cares about what will be sustainable for your brand and for the planet.

Custom Knits: Whether you want a specific knit, color, print, organic cotton or even pre shrunk

House-Made Stock in PFD: This unique offering speeds up your production timeline by providing ready-to-dye fabrics.

Working with Greene Textile feels like having a fabric manufacturer who listens and adapts to your creative vision. It’s like having a trusted teammate in your corner, helping you bring your ideas to life with quality and care.

Tips for Working with a Fabric Manufacturer Like Greene Textile

If you’re new to fabric manufacturing or looking to switch suppliers, here are some tips to get the most out of your partnership:

Be Clear About Your Needs: Share your design goals, fabric preferences, and timeline upfront. The more details you provide, the better they can serve you.

Request Samples and Swatches: Let us know realistic expectations if looking for something that we stock in PFD because you are doing small production and are going to garment dye. On the flip side, let us know if you have been doing production minimums.

Plan for Lead Times: Even with local production, custom fabrics take time. Plan your production schedule accordingly. Some processes we can not rush, like knitting and dyeing, The sooner the better. We need at least 3-4 weeks for a production order of PFD. For custom colors we need 6 weeks which included doing a lab dip and getting it approved. If you need to make garments the same week you order fabric we recommend looking at stock option

Communicate Regularly: Keep in touch with your manufacturer throughout the process. Quick feedback can prevent costly mistakes or miss deadlines.

Explore Sustainable Options: If eco-friendliness matters to your brand, ask about organic or recycled fabric options.

By following these steps, you’ll build a strong relationship with your fabric manufacturer and ensure your products meet your standards.

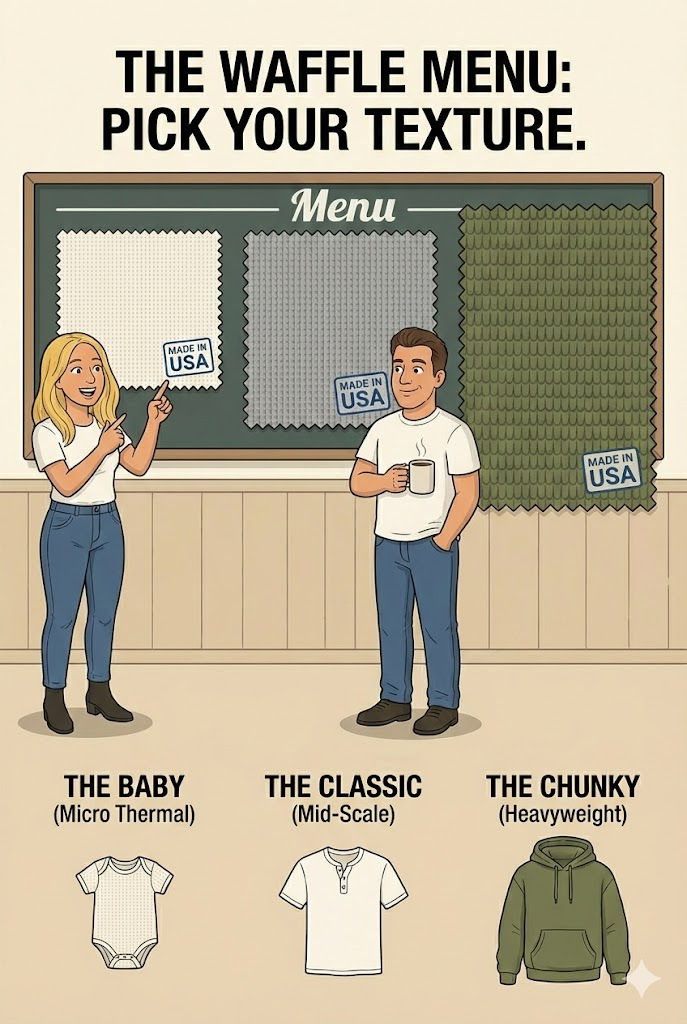

Manufactures have thousands of stitches in their library it is helpful to narrow down the perfect fit if we know we are not over extending micro brands or limiting even small brands.

Bringing Your Fabric Ideas to Life

At the end of the day, fabric is the foundation of your clothing brand or design project. Choosing the right manufacturer can make all the difference between a smooth production process and endless headaches.

If you want a partner who offers custom knits, organic fabrics, low minimums, and local production, then Greene Textile Montebello is worth considering. Their approach combines quality, speed, and sustainability in a way that supports your creative journey.

So, why wait? Take the first step toward fabric success by exploring what Greene Textile has to offer. Your next collection could be just a few yards of fabric away from becoming a reality.

Comments