Understanding Different Types of Rib Fabrics

- Ira Bashist

- Oct 1, 2025

- 5 min read

When it comes to creating comfortable, stylish, and durable clothing, the fabric you choose plays a huge role. Rib fabrics are a favorite among designers and brands for their unique texture and stretch. But what exactly makes rib fabric so special? And how do you pick the right type for your next project? Let’s dive into the world of rib fabrics and explore the different types, their uses, and why they might just be the perfect fit for your clothing line.

Why Rib Fabrics Matter in Clothing Design

Rib fabrics are like the unsung heroes of the textile world. They offer a combination of flexibility, durability, and aesthetic appeal that’s hard to beat. Imagine a fabric that hugs the body just right, stretches when you move, and bounces back without losing shape. That’s rib fabric for you.

One of the reasons rib fabrics are so popular is their structure. They are knitted with a pattern that creates raised vertical lines, or "ribs," which give the fabric its characteristic look and feel. This structure not only adds texture but also enhances the fabric’s elasticity. It’s like the fabric has a built-in spring, ready to move with you.

For clothing brands and designers, rib fabrics provide a versatile base. Whether you’re making cozy sweaters, fitted cuffs, or stylish dresses, rib fabric can add that extra touch of comfort and style. Plus, with options ranging from organic cotton to blends, you can align your fabric choice with your brand’s values and customer expectations.

Close-up view of rib fabric texture showing vertical ribs

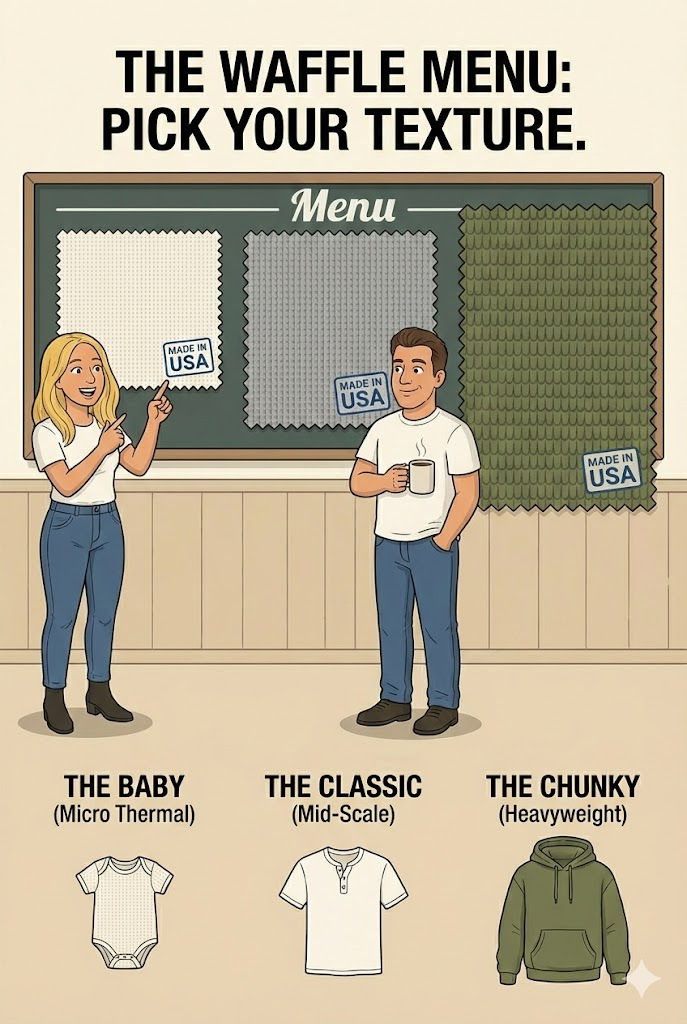

Exploring the Types of Rib Fabric

When you hear "rib fabric," you might think it’s just one kind of material. But rib fabrics come in various types, each with its own unique characteristics and best uses. Understanding these types can help you make smarter choices for your designs.

Here are some common types of rib fabric you’ll encounter:

1x1 Rib Knit: This is the most basic rib knit, with one knit stitch followed by one purl stitch. It’s stretchy and has a fine rib pattern. Perfect for cuffs, collars, and waistbands.

2x1 Rib Knit: This type has two knit stitches followed by two purl stitches, creating a wider rib. It’s thicker and more durable, often used for sweaters and heavier garments.

Interlock Rib: This fabric is double-knit, giving it a smooth surface on both sides with ribbing in between. It’s stable and less stretchy, ideal for structured pieces.

Each type offers different levels of stretch, texture, and weight. Choosing the right one depends on the garment’s purpose and the feel you want to achieve.

Eye-level view of folded rib knit fabric rolls in various colors

What are the different types of rib fabric?

Let’s break down the different types of rib fabric in more detail, so you can see which might work best for your needs.

1x1 Rib Knit

This is the classic rib fabric you often see on t-shirt cuffs and necklines. It’s lightweight, very stretchy, and has a fine rib pattern. Because of its elasticity, it’s great for areas that need to stretch and recover, like sleeve cuffs or neckbands. It’s also easy to sew and works well with most yarns.

2x1 Rib Knit

If you want something a bit thicker and more textured, 2x2 rib knit is your go-to. It has a chunkier rib pattern and offers more warmth and durability. This type is often used in sweaters, cardigans, and heavier tops. It holds its shape well and adds a cozy feel to garments.

Interlock Rib

Interlock rib is a double-knit fabric that’s smooth on both sides with ribbing sandwiched in between. It’s less stretchy than other rib fabrics but offers excellent stability and a clean finish. This makes it ideal for structured garments like dresses or fitted tops that need a bit of firmness without sacrificing comfort.

Other Variations

There are also blends and organic options available, which combine rib knit with other fibers like spandex for extra stretch or organic cotton for sustainability. These variations allow you to customize your fabric choice to fit your brand’s ethos and the needs of your customers.

High angle view of organic cotton rib fabric rolls stacked

How to Choose the Right Rib Fabric for Your Project

Choosing the right rib fabric isn’t just about picking the prettiest texture. It’s about matching the fabric’s properties to your garment’s function and your brand’s values. Here are some tips to guide you:

Consider the Stretch and Recovery

If your design needs to hug the body or stretch frequently, go for 1x1 or 2x1 rib knits. They offer excellent elasticity and bounce back well.

Think About Weight and Warmth

For lightweight garments, 1x1 rib is perfect for t-shirts. For something warmer and more substantial, 2x1 to pair with French Terry, Fleeces and Thermals

Look at the Fabric Content

Cotton rib fabrics are breathable and soft, while blends with spandex add stretch. Organic cotton options align with sustainable brand values.

Check the Fabric Stability

Interlock rib fabrics provide more structure and are less prone to stretching out of shape, ideal for fitted dresses or tops.

Match Your Production Needs

If you need quick turnaround and consistent quality, consider working with a local manufacturer that offers house-made stock in PFD (Prepared For Dyeing) with low minimums. Most manufactures will dye the rib trim for lower minimums with the main fabric. As long at the total yardage for custom colors or prints meet the minimums you can order as low as 100 yards of house rib to go with your 800 yards of Fleece.

By keeping these factors in mind, you can select a rib fabric that not only looks great but performs well in everyday wear.

Why Work with a Local Manufacturer for Rib Fabrics?

When sourcing rib fabrics, partnering with a local manufacturer can be a game-changer. Here’s why:

Speed and Flexibility: Local manufacturers can often provide faster turnaround times and accommodate smaller orders. Our low minimums come from our house-made stock in PFD, which means you get access to quality fabrics without waiting months or ordering huge quantities.

Quality Control: Being close to the production source means you can oversee quality more easily. This ensures your fabrics meet your standards and your customers’ expectations.

Customization: Local manufacturers are more likely to work with you on custom colors, blends, and finishes. This flexibility helps your brand stand out with unique fabric choices.

Sustainability: Reducing shipping distances lowers your carbon footprint. Plus, many local manufacturers prioritize sustainable practices and organic materials.

If you want to explore a variety of rib fabric types with the convenience of local production, working with a manufacturer that understands your needs is a smart move.

Bringing It All Together: Your Next Steps with Rib Fabrics

Now that you have a clearer picture of rib fabrics and their types, it’s time to put that knowledge into action. Whether you’re designing a new collection or refreshing your basics, rib fabrics offer a blend of comfort, style, and durability that’s hard to beat.

Here’s a quick checklist to help you move forward:

Review your garment designs and identify where rib fabric could enhance fit and comfort.

Choose the rib fabric type that matches your design’s stretch, weight, and texture needs.

Ask if they have a house rib. Typically they can offer better pricing and lower minimums. It has also been perfected and widely used with most of their fabrics.

Most manufacture won't tweak a style an ounce or percentage on spandex. It's also not common to make sample rolls for ribs, unless the production order is for 1,000 yards.

Consider fabric content and sustainability to align with your brand values.

Reach out to a local manufacturer with house-made stock in PFD and low minimums to get samples and pricing.

Test the fabric in prototypes to see how it performs in real wear.

Remember, the right fabric can elevate your clothing line from good to great. Rib fabrics are versatile, reliable, and stylish - a perfect combination for any brand looking to make a mark.

Happy designing!

Comments